Location: LTEC Dried Chilli Processing Factory is Located in Shabbir Feed Mills, Multan.

Factory Layout: LTEC Dried Chilli Processing Factory is Located in Shabbir Feed Mills, Multan.

Pest Management: LTEC has a contractual partnership with ECO PEST Solution for complete pest management services at LTEC Dried Chilli Processing Factory.

System Assure: Following the Chinese food factory management system, we have established a scientifically rigorous system and are actively implementing it to guarantee that dried chillies conform to China’s import standards.

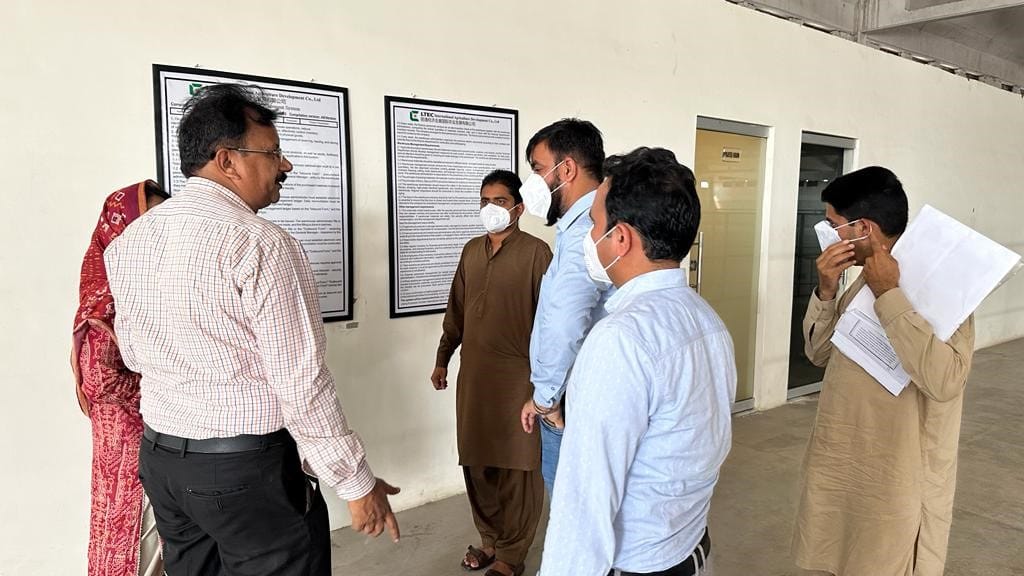

Inspections by DPP Department:

Dedicated Areas for each Step:

Package & Labelling: LTEC follows rigorous packaging and labeling management measures, ensuring that all products are packaged securely and labeled accurately.These measures include the use of clean and compliant packaging materials, dual-language labeling in Chinese and English, proper product identification, and adherence to all relevant regulations and safety standards. This approach guarantees the quality, traceability, and safety of our products from production to distribution.

Raw Material Storage: Raw Materials are stored in a dedicated and separate warehouse or storage space. This practice is essential to maintain the quality and integrity of the raw materials and prevent cross-contamination, ensuring the safety and quality of the final products.

Trainings:

- LTEC, we provide relevant training to our operators and technicians in accordance with the requirements specified by China.

- Such training ensures that our staff is well-informed and proficient in the processes, regulations, and safety measures that are essential for our operations.

- It helps maintain compliance and quality standards while also enhancing the skill and knowledge base of our workforce.

Hygiene and Safety: LTEC, our factory, places a high priority on epidemic prevention and hygiene measures to ensure the safety and well-being of our employees and visitors. In addition to strict adherence to wearing face masks and gloves, we have also made hand sanitizer readily available throughout the facility.

Laboratory: We maintain a dedicated laboratory equipped to conduct basic tests on received chilies, specifically for assessing moisture levels to ensure product safety and restrict aflatoxins in our final products.

Packaging: LTEC, shipments are supervised and often sealed to maintain the integrity and safety of the products during transit.This practice helps ensure that the products reach their destination in the same condition they were in when they left the facility and that they have not been tampered with or compromised in any way.

Traceability Management System: We have implemented a robust traceability management system within our processing plant to ensure transparency and efficiency at every step of our operations. Our system involves a well-structured check-in and check-out process at each stage, which is meticulously executed by every department involved in the production process.

Finished Product: Finished products are stored according to batch identification. This practice allows for efficient tracking, quality control, and traceability, ensuring that products can be easily identified and managed throughout their storage and distribution.